In June 2020 we have published the names of the 12 pilot companies that decided to participate in E2DRIVER, increase their energy efficiency and thereby contribute to the global effort to reduce carbon emissions. In a four-part series, pilot companies from the four participating countries – Germany, Spain, Italy and France – will present themselves, their views on why energy efficiency is important to their operations and why they decided to join E2DRIVER.

The first issue presents the three pilot companies from France – ERCÉ Plasturgie, Manuplast and Nanomakers. In their introduction below you can get to know the companies, understand their motivation to reduce energy consumption and learn how E2DRIVER can help them achieve this goal!

Ercé Plasturgie

Why do you consider energy efficiency important in your company?

Ercé Plasturgie is specialized in the industrialisation and the sale of technical components manufactured by plastic injection and automated assembly for the automotive industry. For our company, the energy efficiency of our production processes is an increasingly important issue.

The reduction of these costs and the sustainability of our productive investments are indeed a major factor to face international competition. Likewise, as a Europe-wide organisation, our company is fully committed to achieving the Union’s environmental objectives. Our site in Hranice in the Czech Republic is already ISO14001 certified, but not our site in Athis, Normandy. This is why energy efficiency must become a main concern for our quality development managers, who are now an integral part of all our projects.

Ercé Plasturgie is keen to strengthen its expertise on energy auditing, to identify energy-intensive or energy-consuming jobs, but also to search for energy-saving practices related to our business. All of this will enable us to set precise performance indicators that are known to everyone, the evaluation of which will enable us to progressively improve the energy efficiency of our processes.

Why did you choose to participate in E2DRIVER?

Ercé Plasturgie’s commitment to energy efficiency can only be achieved if all our teams develop a genuine savings culture. This is the very philosophy of the BEEP (well-being and performance) system we launched in 2015, which aims to initiate a cultural transformation in the company for greater responsibility at all levels and better communication. This is exactly why E2DRIVER meets our needs, as the project propose to identify training needs differentiated by role and profile, in order to better adapt the available training material to each person within the company.

The start of the project indeed confirmed that knowledge of energy efficiency issues was uneven within the company. A majority of our teams have not benefited from courses or seminars about measures to increase energy efficiency associated with its tasks. This is why Ercé Plasturgie is particularly interested in participating – and benefiting from – the development of innovative training material, online lessons, guidelines, energy and financial tools, virtual reality modules on these issues.

Finally, and again as a Europe-wide organisation, Ercé Plasturgie is enthusiastic about the idea of being in contact with the E2Driver community, gathering large automotive manufacturing companies, energy auditors, energy experts, financing entities, engineering firms and other key players throughout Europe.

Ercé Plasturgie’s plastic component

Manuplast

Why do you consider energy efficiency important in your company?

MANUPLAST has always been a pioneering company on sustainable development topics in Normandy. We proceeded in two rounds of Energy -20 (with carbon footprint audit). It is a natural continuation for MANUPLAST to implement energy requirements in our SMP (Performance Management System), for instance with ISO 50 001 guidelines.

Sustainable development is part of corporate social responsibility of course, but also self-evident for pollution and costs reduction. It will be soon a mandatory requirement for all companies, especially industries. MANUPLAST wishes to be ahead of the game. Working on energy efficiency also allows to improve company organization generally speaking, for example in workflow management. As a conclusion, it is a great opportunity and a mean to manage environmental risk and ensure conformity to regulations.

Why did you choose to participate in E2DRIVER?

MANUPLAST chose to participate in E2DRIVER because it gives access to a methodical support from experts. Engaging with external actors with credentials and experiences different from plastic transformation will be a great opportunity to record best practices from other activities and points of view.

As a member of Move’o for more than ten years, it was important for MANUPLAST to keep up the innovation momentum on environment and energy topics. E2DRIVER is also a European approach that goes in the right direction from the company’s point of view. Finally, because of the E2DRIVER project, our lead team will have the opportunity to develop its skills and all MANUPLAST will benefit from operational improvements.

Manuplast’s production facility

Nanomakers

Why do you consider energy efficiency important in your company?

Nanomakers considers energy efficiency as a major point in our company for different reasons. First of all, whether it comes from electricity, natural gas, or other sources, energy is costly. It is then financially interesting to reduce the consumption of energy within our company. But the financial advantage is only the tip of the iceberg. For instance, by reducing our consumption of energy, with the use of scheduled on/off switches for some equipment (which are not useful at night), we also reduce wear and tear on our facilities, which also indirectly reduce our investments cost, and therefore our ecological footprint because we need less investments and less maintenance consumables.

Second, using less energy means directly reducing the quantity of carbon emissions related to the production of this energy. This reduction of carbon emission is one of the most crucial aspects, even if the impact of its reduction is not directly visible for Nanomakers. If all the companies make efforts in this direction, tangible results will be observable, such as the limitation of global warming.

Finally, if Nanomakers can reduce its energy consumption, our customers will also be positively impacted. If they consider how carbon-intensive their final product is, based on how carbon-intensive each primary product is, they will observe a reduction in their final product, as a consequence of the carbon reduction of Nanomakers’ product. This may account as a qualitative discrimination in front of competitors.

As a conclusion, energy efficiency is an issue where all players are winners: environment, our customers and Nanomakers itself.

Why did you choose to participate in E2DRIVER?

When Nanomakers got in touch with the E2DRIVER project team, we were already aware of the topical issue of energy efficiency for the company. However, it is not always trivial to implement the means to get there, which is why the expertise brought by the E2DRIVER project is invaluable. In addition, Nanomakers was also interested in the innovative structure of the project, which takes place in two parts, first with the construction of a training course, then with its deployment.

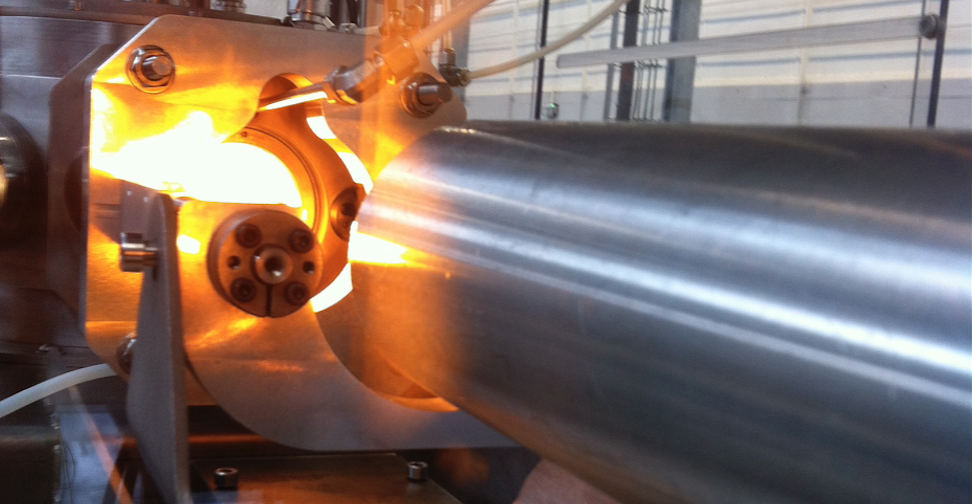

Production process at Nanomakers